MVP Large Series (240m3/h)

Design Features

- Excellent ultimate vacuum and pumping speed by suing high performance new materials.

- Improved oil anti-suckback system to protect the vacuum system in the event of sudden stop.

- Occupying international standard clamp and flange at inlet and outlet port.

- Low noise and vibration.

- Occupying strong and constant pressured oil circulating system to protect the pump.

- Occupying convenient gas ballast valve control enabling open and shut-down of gas ballast valve easily while operating.

- Simple maintenance and oil replacement.

- Simple repair without special tools.

MVP Large Series (240m3/h)

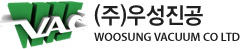

External Pump Sketch

Technical Data

| DESCRIPTION | Unit | MVP240 | |||

| DisplacementSpeed | 60Hz | m3/h | 240 | ||

| L/Min | 4000 | ||||

| 50Hz | m3/ | 200 | |||

| L/Min | 3400 | ||||

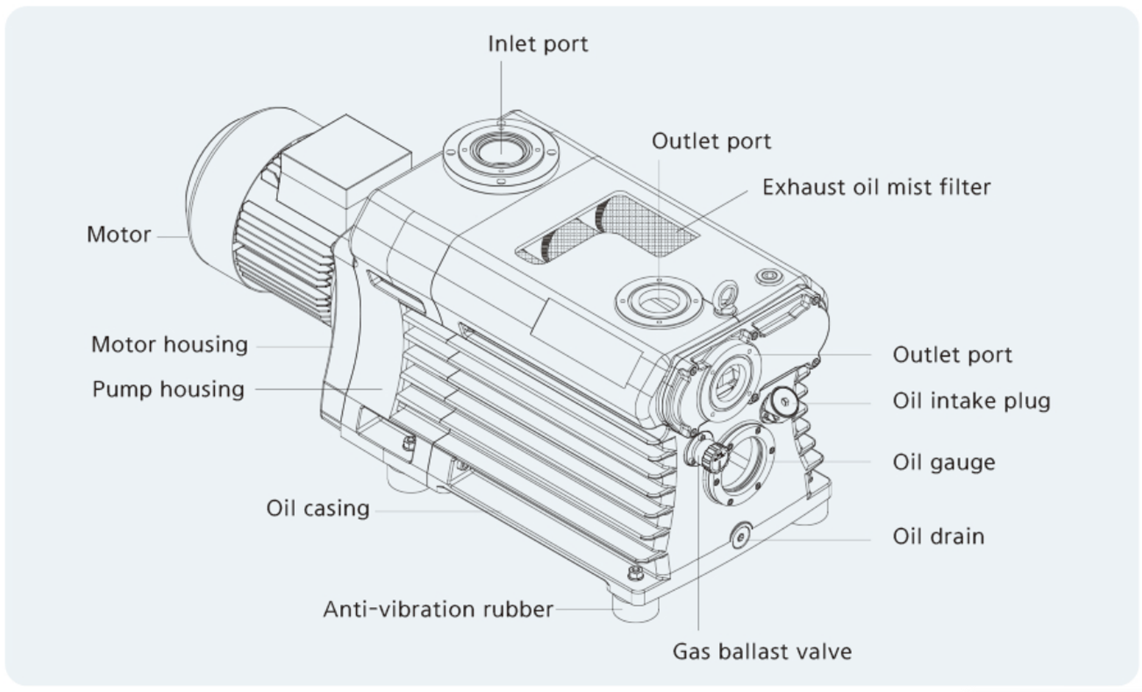

| UltimatePressure | With gas ballast | Torr | 5 x 10-3 | ||

| Without gas ballast | 5 x 10-4 | ||||

| Inlet Port | ISO 63 | ||||

| Outlet Port | ISO 63 | ||||

| Motor Power | kW | 5.5 | |||

| Rotational speedof Pump | 60Hz | R.P.M | 1750 | ||

| 50Hz | 1450 | ||||

| Oil Filling | Liter | 13 | |||

| Weight | kg | 200 | |||

Pumping Speed Curve

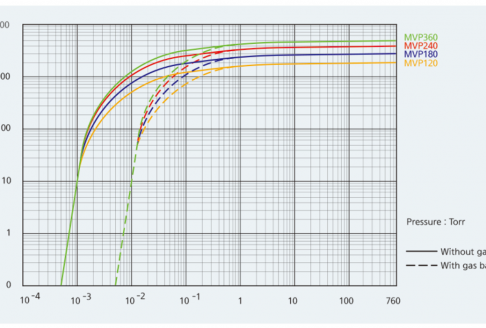

Outside Dimension (Model : MVP 240)

(unit:mm)

|

Model |

A | B | C | D | E | F | G | H | I | J | K | L | M | N |

| MVP240 | 360 | 430 | 486 | 395 | 470 | 521 | 55 | 40 | 153 | 332.5 | 78 | 380 | 1022 |

M12 |

Design Operation Principle

- MVP Series is two-stage oil sealed rotary vane vacuum pump. It is new concept out of conventional design to satisfy customer’s needs.

- The structure of the pump

It consists of pump housing, oil casing, motor housing, pump base and pump module. It occupies oil anti-suckback valve and gas ballast for protecting pump and vacuum system. - Operating Principle

The pump and motor are connected by flexible coupling. As the rotor rotates two vanes, placed in rotor vane groove, turn making contact with the internal surface of the cylinder due to centrifugal force.

The inhaled gas is trapped between two vanes as the rotating vane passes through the inlet passage and this trapped gas is compressed as it rotates toward exhaust valve and eventually exhaust through valve. The vacuum oil is supplied to the moving parts for lubrication and tight sealing.